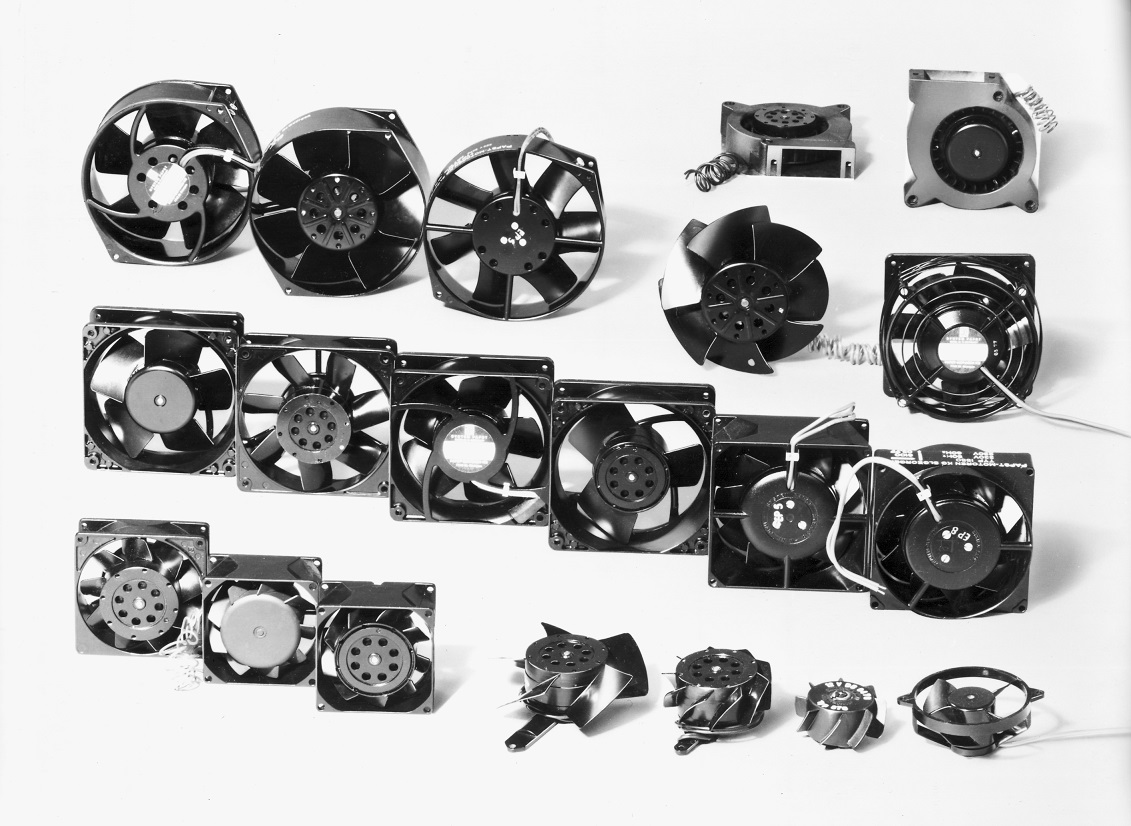

Corner enlargement in axial fans

Large Volume Fans increasingly become the source of sales for the company

–

The digital telephone and communication technology, with its high power requirements, would be unthinkable without external ventilation/cooling. Every known company working in this field uses the “Papst-Electronic Device Fan” right from the start. The heat dissipation of mobile base stations is no exception. Leading, European manufacturers like Siemens, Ericsson, Nokia, Alcatel, Telefonica or British Telcom become important costumers.

Because of its surrounding casing in the shape of a hub, the external rotor motor is especially suited for axial and radial fans. Hermann Papsts fan is made based on an external rotor motor in which the hub directly carries the fan blades. The soldered or welded fan wings add up to an excellent heat dissipation which again allows the motor to work at higher power levels.

Venturi shaped axial fans, i.e. with rotors inside of a cylindrical tube, were commonly used. But the market demanded a greater airflow output and more pressure while still using an unchanged mounting cross section. The first part of the solution was to maximise the impeller diameter in the cylindrical flow chamber, the second was to open the chamber towards the four corner mounting positions of the fan. The fan stayed compact but became quieter and more efficient. German Patent Nr. 1728338.

The external rotor motor was perfect for a broad variety of types of axial and radial fans. Fans with an external rotor motor are made up of less parts and are very well suited for economical manufacturing in large volumes. Papst MOTOREN & Co. KG became the most requested provider of cooling fans worldwide.

Firstly IBM-manufacturing plants located in European countries were supplied. The Computer-Division of IBM was convinced quickly to use the fans, because of the smooth running and the durability of their external rotor and satisfying further parameters like volume, pressure, and minimal noise design inside of the IBM type lever typewriter. Soon competitors like Hewlett, Packard, NCR, Digital and other international manufacturers followed and became costumers as well. In Germany Nixdorf, Siemens and all the other European manufacturers of Office and Computer Devices started to buy fans. In the beginning the fans were equipped with Capacitor-External Rotor Motors, later on with shaded pole windings. The programme was expanded with more efficient types, with shaded pole motors, Capacitor motors and later on with DC motor drives. In 1959/1960 the senior and junior partners Purdy called on the Papst-company to inform the directors that they were interested in selling the fans in the western part of the USA, because of their high quality. The exclusive marketing of fans for the USA and for Canada began on the basis of a contract for 50.000 fans.

Papst-Motoren & Co. KG approved their partner’s fan- marketing organisation divisions- and product name “Pamotor”, which soon expanded over the entire American continent. Accordingly every big city in the USA and Canada, already had the companies entire fan programme at their warehouses for the prototypes of new devices. A big advantage was that it had already approved the fan for the frequent production relocations to Europe which took place later on.

Thanks to the efficient External-rotor systems in axial and radial fans, not only the market share in the USA could be increased, even in Europe the company stayed the strongest main and sometimes even sole provider, when it came to axial fans, or fans for devices (for example with Siemens for all applications). The fans marketed as a component part with mounting dimensions and a product standardized for trade has had a positive development in Europe. With 25% of the blower sales volume it has become an important economic market segment.