Injection and Combustion concepts for Combustion Engines

–

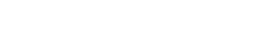

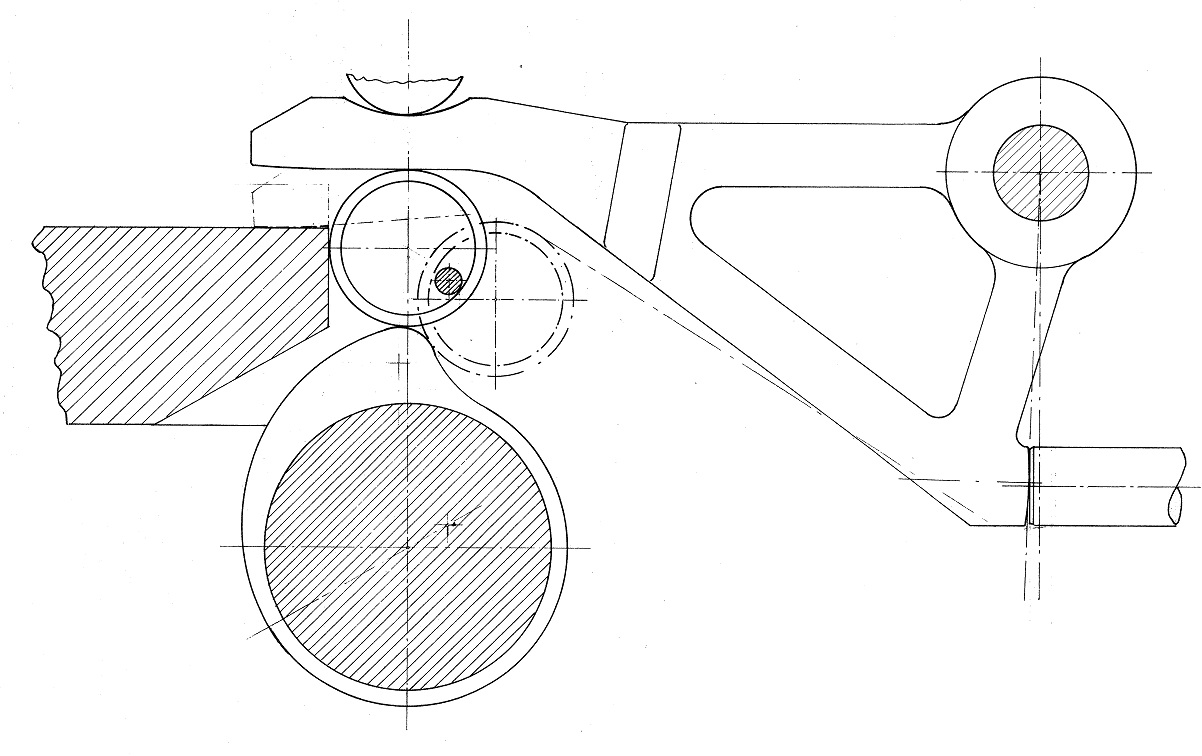

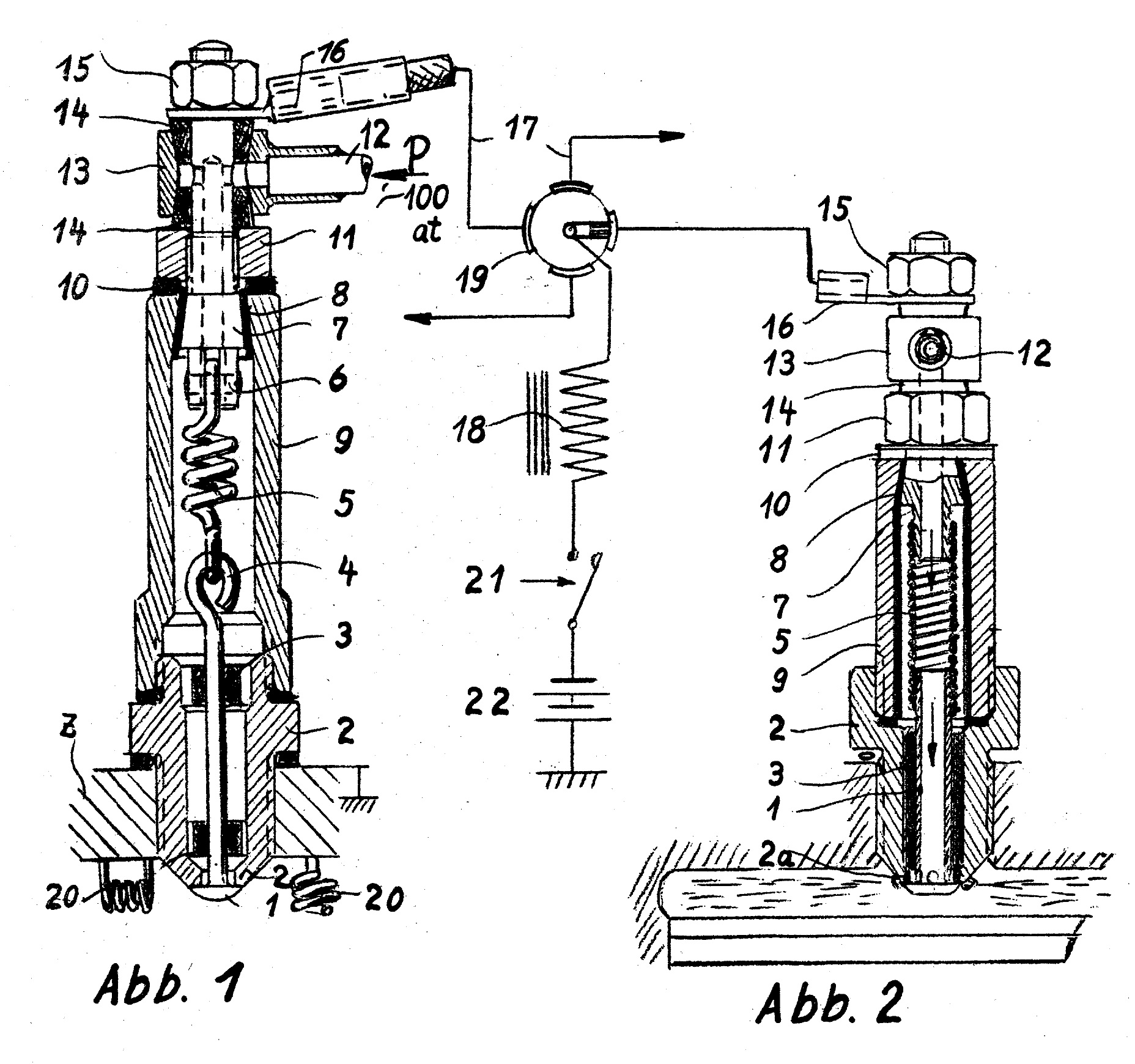

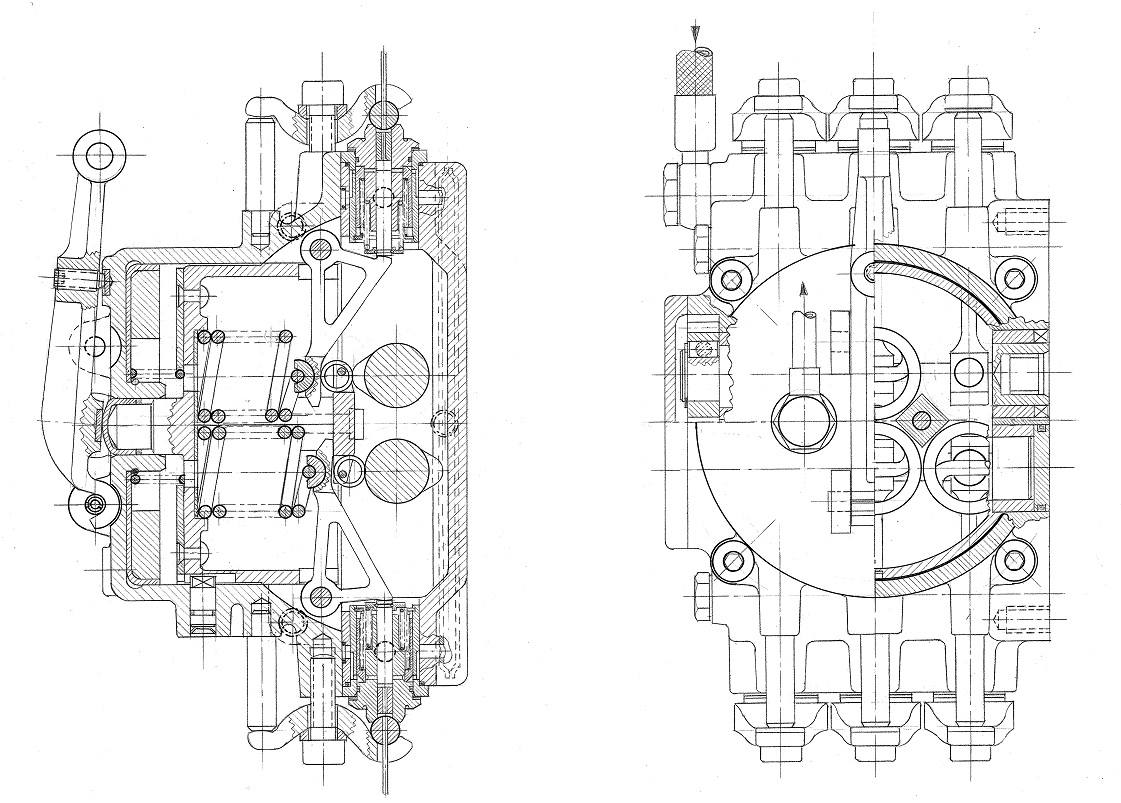

Injection Pump: To achieve a proper combustion in small diesel engines, it is necessary to inject a small amount of fuel within the shortest period of time under the highest pressure possible into the combustion chamber. This challenging task lead to a lift mechanism injection pump, with an injection characteristic pressure that was independent from revolution speed, with a sliding tappet sloping over the edge of a cam, driven by a spring.

Already in 1975 extraordinary results for the injection pressures of about 1000 atm could be reached, even with low revolution speeds. Besides the DPS 1 476 235 (lift mechanism injection pump) about 15 additional German patents and many foreign patents were granted.

–

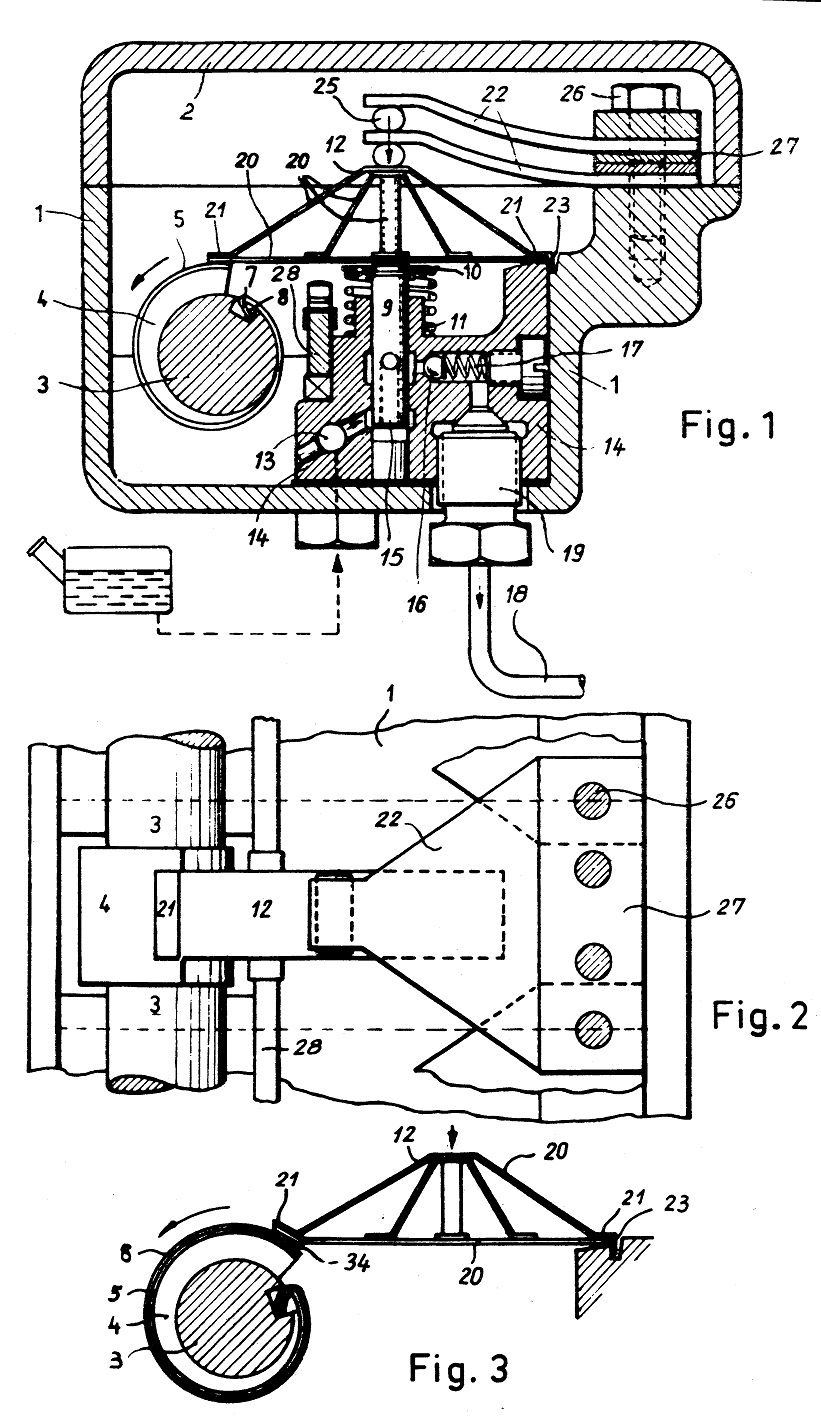

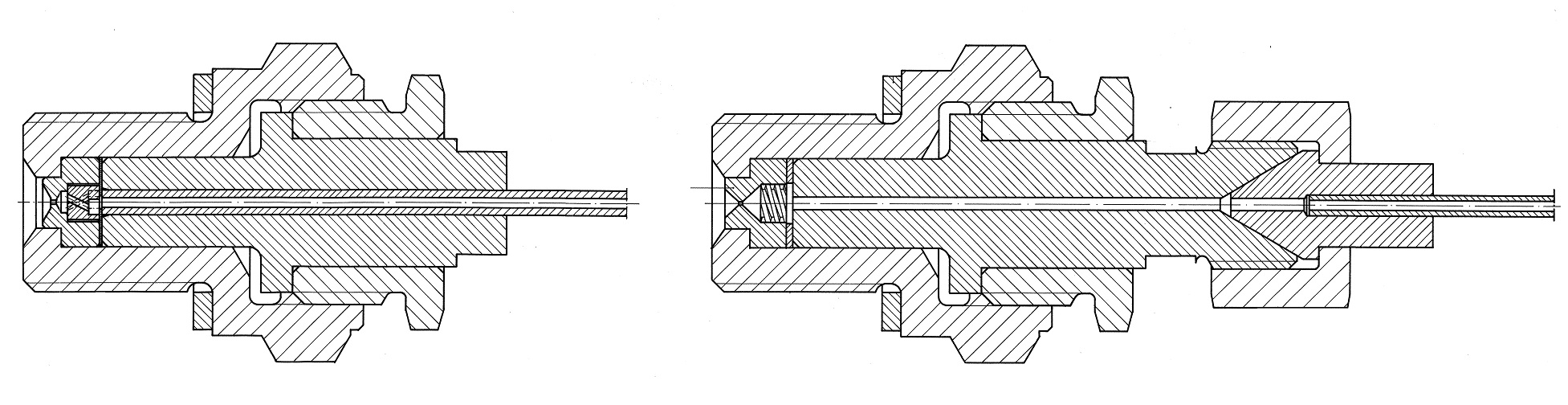

Injection Nozzle: The injection nozzle was designed as an annular gap ignition nozzle. A discharger is created between the center electrode and the ring shaped counter/return electrode, through which the combustion is ignited when the fuel ray enters.

Hermann Papst was sure that the effect is bigger if the flame is injected, instead of the unignited fuel. For years he works on optimizing the injection procedure.