Starting an industrial enterprise

–

Fast-growing industrial enterprise

With the growth of the German economy after the currency reform, the demand for small motors grows exponentially. As a small motor the Papst External Rotor Motor is ideal as a constant and smoothly running drive for tape recorders (sound-tape, magnetic wire, magnetic tape). There is a huge demand for entertainment devices, office equipment like dictating machines, electric typewriters, accounting machines, as well as tape recorders. Because of that, companies like Schaub-Lorenz, Tefi, Löwe-Opta, LM Ericsson, Grundig, IBM, Triumph-Adler and Olympia provide large orders for respective motors. In addition special applications in precision technologies and engineering come in. Including all family members, the company is turned into a family owned partnership named Papst-Motoren KG in 1952.

Hermann and Mathilde Papst with their 5 children (picture taken around 1956)

form the partners of shareholders of the Papst-Motoren KG.

–

–

The company’s massive expansion from 1950 to 1960 is closely connected to the Grundig company, which uses Hermann Papsts direct-driving External Rotor Motor temporarily exclusively in large volume series.

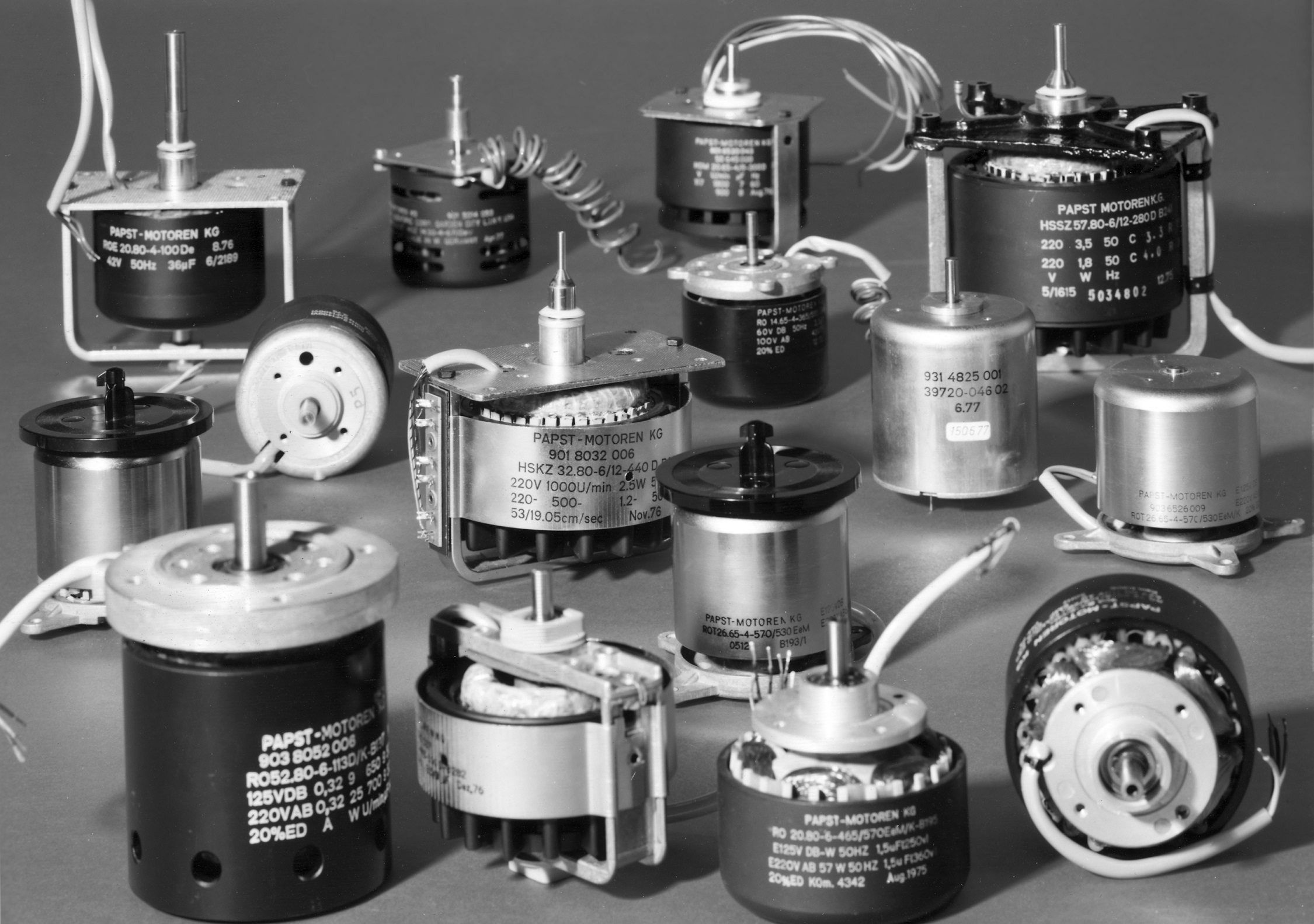

External Rotor Motors for professional tape recorders and studio tape recording machines

–

In the Comecone (Economic Society of the former Eastern bloc countries) Hungary was responsible for the manufacturing of professional devices in studios, as well as for continuously operating systems in air-traffic and telephone surveillance. Fifty percent of the devices were exported into the SSSR, the remainder into Eastern Europe, Arabic countries and Cuba. Because of the weakness of the Eastern bloc’s political system, there was no hard currency left at the end of the 1970s to pay for the Papst-Motors, which almost lead to the termination of the device production. To improve the situation, a contract for producing in Hungary was made in the 1970s/1980s, first for the manufacturing of windings and motor parts (printed circuit boards), later on for fans and motors. The new site with lower wages than in West-Germany was needed urgently, to be able to compete with companies from the far east.

This was the origin for a continued expansive production engagement in Hungary, later on in multiple other locations with several hundred employees.

–

In the wake of large volume demand

Manufacturers of office machines, like IBM and Triumph-Adler give a strong impel towards expansion. Hermann Papst has to design new drives for electric type writers and accounting machines for typewriters using the lever system individually for both manufacturers on short notice. For one of them he has to start the volume production within in a matter a few weeks, because of the failure of the current foreign suppliers.

The External Rotor Motor (in the meantime known as Papst-Motor) is especially attractive due to its design principle, along with an exceptional manufacturing quality, extremely steady and efficiently constant run. It is not surprising regarding the motors qualities, that it is used frequently for lab equipment (thermostat and magnetic mixer), precision- and medicine technology, textile technology and many other areas.

Winding technology of the companies first years, around 1950

–

materials competence and efficient manufacturing

The enterprise in St. Georgen combines automation with the flexible use of craftsmanship labor in winding assembly, because the combination of both processes represents a considerable element of quality assurment and improvement.

Hermann Papst’s universal work is more than design and demonstrates his unusual capability of connecting theory and practice. The secret of his success as an engineer-entrepreneur also lies within his foresighted perspective, endurance and systematic profundity with which he pursues and optimizes his products and subjects them to rigid quality demands.

Inserting preformed coils into the stator

–

Hermann Papst believes that the good quality of products has to be ensured right from the start and not through testing-procedures afterwards. Every part of an engine has to be presented as flawless and functional before the cost control even takes place. Many of his production-procedures are transformed into full- or half automatic processes by employees of the factory.

–

First trip to the USA

In fall of 1955 Hermann Papst sets out from Frankfurt am Main to his first trip to the USA for several weeks. His son Günter, who has been working in his father’s company from 1951 on, accompanies him as an interpreter and assistant.

Hermann and Günter Papst travel with heavy luggage: They have not only packed clothes, but also suitcases with sample motors in them. The journey begins at the east-cost and continues all the way to California. Hermann Papst quickly manages to develop business contacts through his direct and sociable nature.

Hermann Papst and his son Günter before their first trip to the USA (taken in 1955)

–

Hermann and Günter Papst quickly realize that there is a high demand for and interest in the External Rotor Motor, because it is mostly unknown in the United States. In the early 1950s colour television for private households is made ready for market. The international renowned radio producer Columbia uses synchronous External Rotor Motors from St. Georgen for the drive to rotate the mechanic colour filter discs system in its prototypes.

The trip results in the international break-through of the “Papst Motor”. The first contracts are accomplished for selling Hysteresis-Synchronous External Rotor Motors to the manufacturers of High-Fidelity record players (which are very popular on the US-market), located in the eastern United States. For more than 10 years the Papst Motoren KG delivers Hysteresis-Synchronous External Rotor Motors for the High-fidelity record players with a belt drive and sets up a corresponding motor-sevice in Chicago. Though it takes almost 13 years until the establishment of a production and sales branch of the later Papst-group in the US commences.